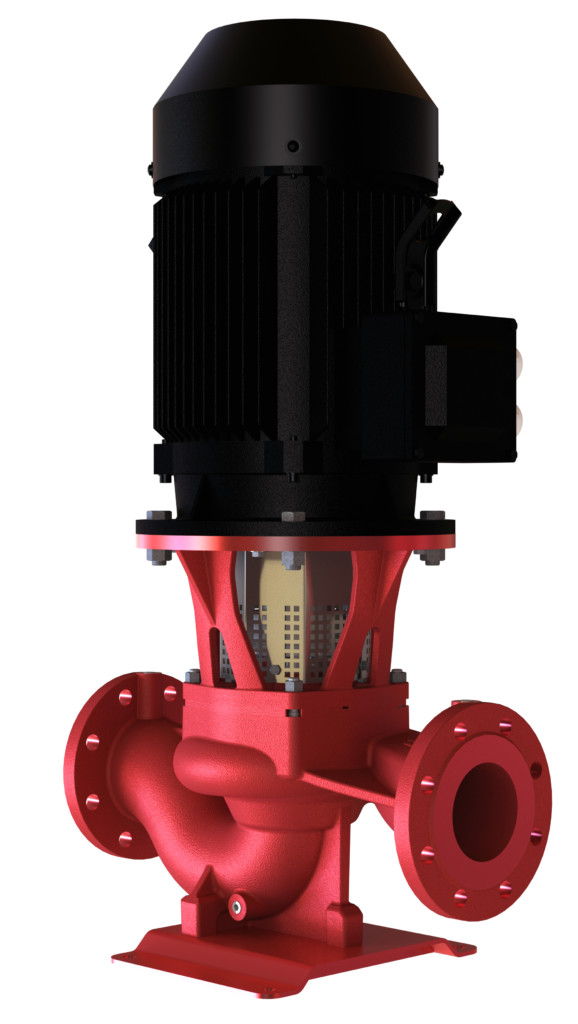

Kolmeks new KI pump series

Premium efficiency

a

a

Excellent performance – Unique design

methods

Revolutionary and innovative methods improving pumping performance.

Effective simulation tools helping quick analyses of various hydraulic designs.

Full-scale research center allowing testing of final design options in real operating conditions.

More reliable and highly effective hydraulics:

=> Higher efficiency hydraulics

=> Higher suction capability impellers

Note:

As a motor manufacturer Kolmeks has testing facilities for electric motors as well

- a

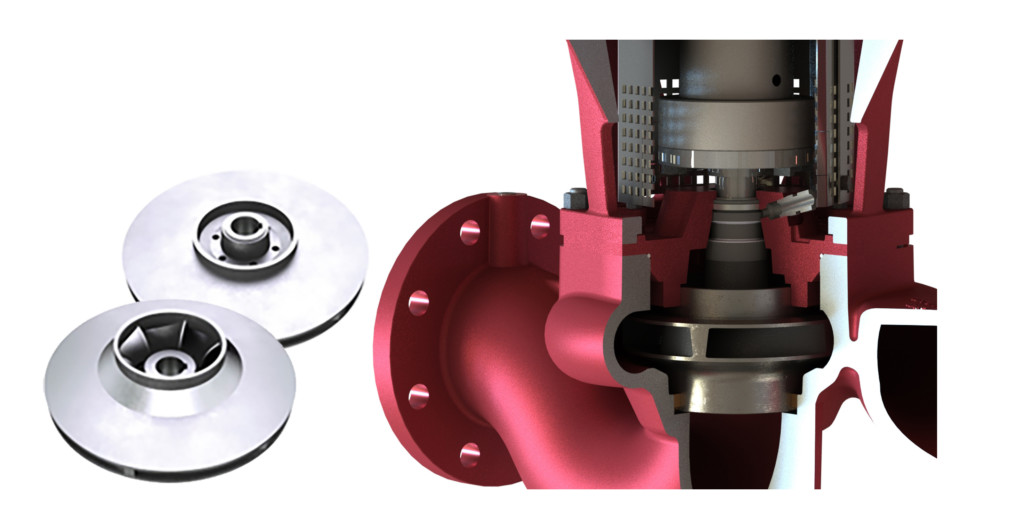

Closed impeller design features and benefits

• For clean and slightly contaminated liquids

• High efficiency

• Low Net Positive Suction Head required (NPSHre)

• Robust and strong design

• Optimized balancing holes for axial thrust balancing

• Bronze wear ring on the suction side of the impeller

• Easy to trim

• Not sensitive to reverse rotation

• Belzona treatment optional

A

A

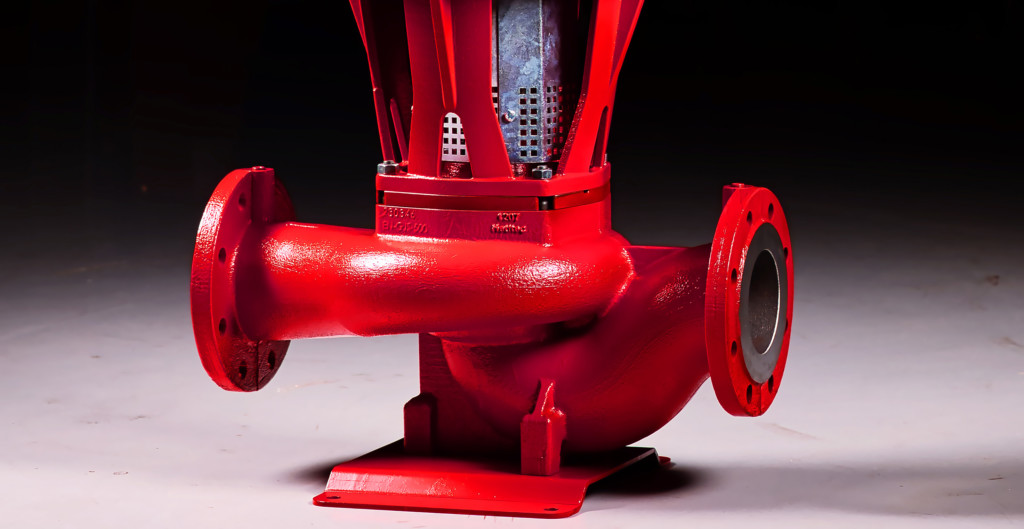

Classic keyway impeller mounting

• Long support between the shaft and impeller minimizes vibration

• Back flow safe

• No axial load variations during pump operation due to good axial load balancing

• Easy and quick dismantling and assembly

• Helps to minimize life cycle costs

Wear ring & impeller balancing holes

• Guarantee optimized flow and pressure in the shaft sealing area

• Dry running of the single mechanical seal is eliminated in a wide operating area

with the help of optimized impeller balancing holes

a

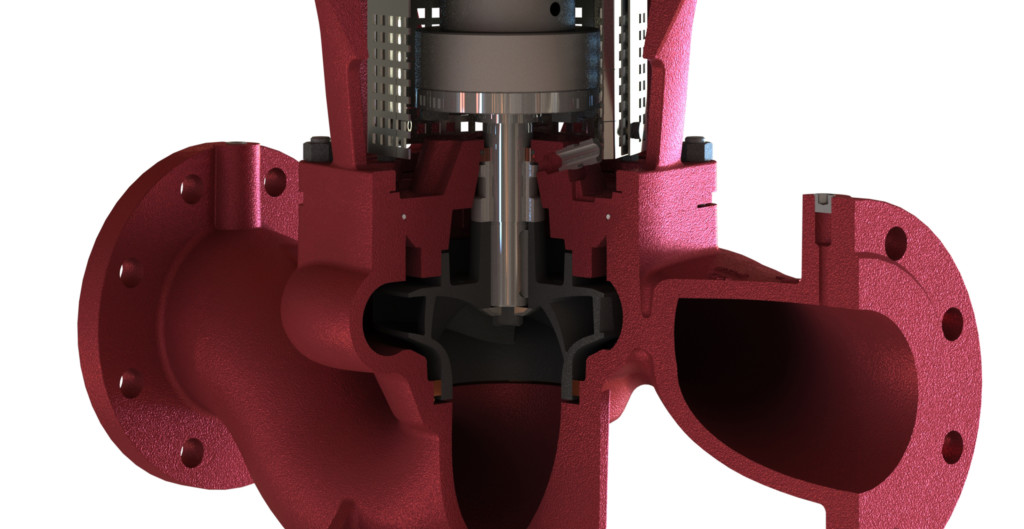

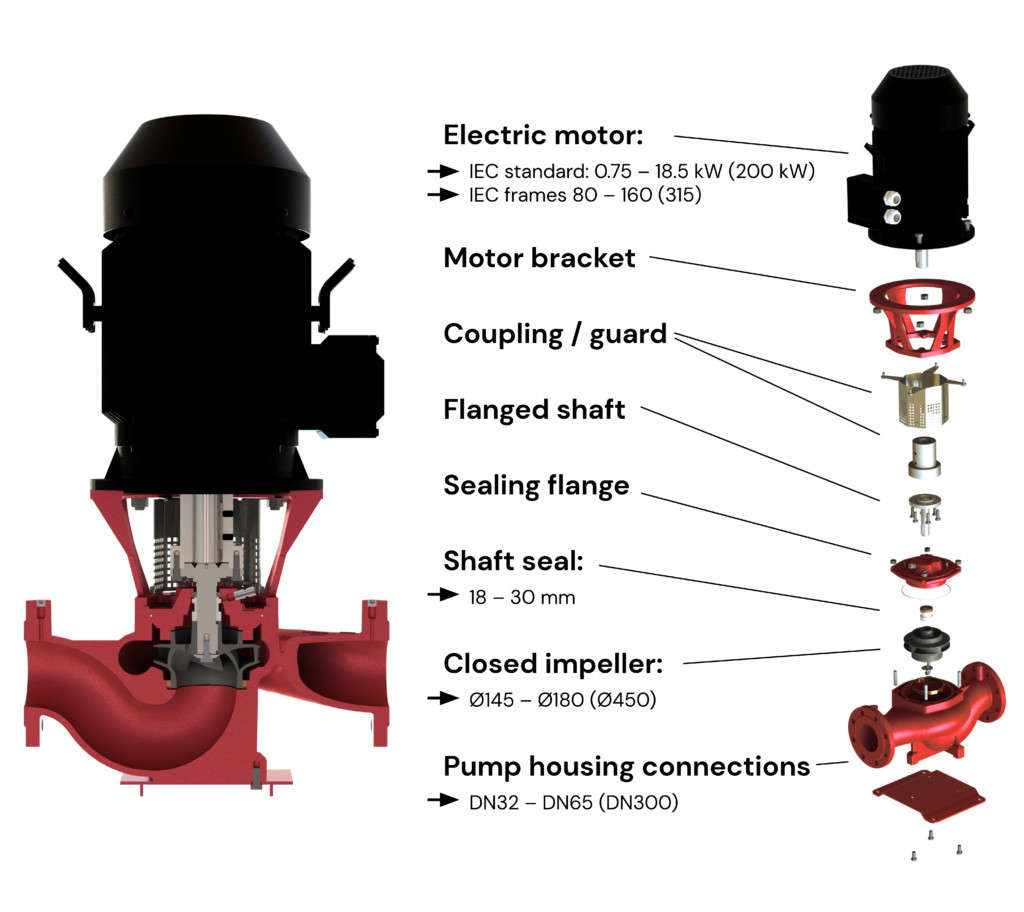

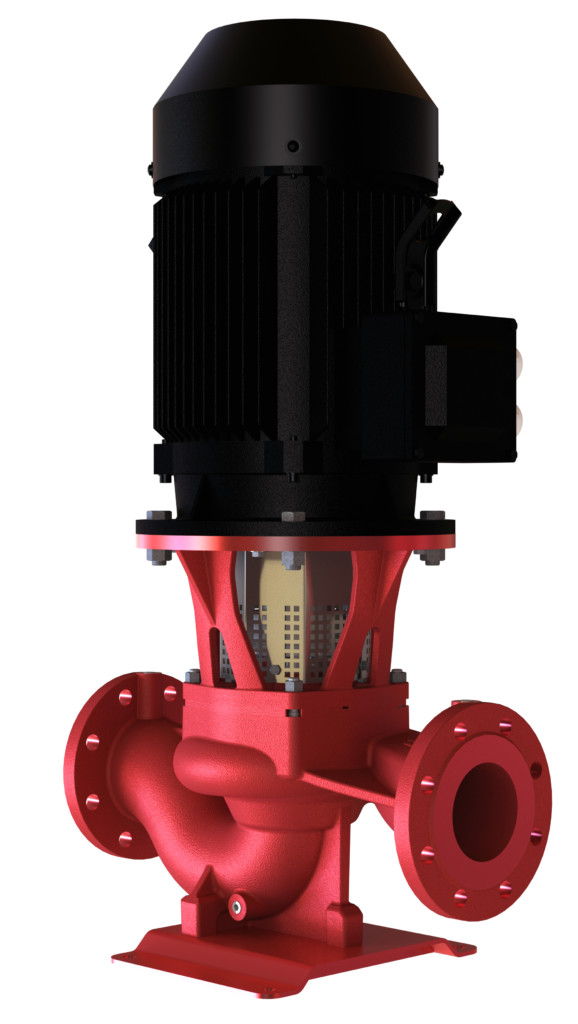

Simple and heavy construction

Low parts inventory – Less components –

Less failures

Simple, compact and heavy duty monoblock construction

Close coupled pump – no separate pump bearings

Optimized impeller design ensures long lifetime

Standard mechanical seals, low vibrations, good sealing conditions

– long mechanical seal lifetime

=> Low maintenance costs

a

Common spare parts:

Mechanical seal

Exchange unit

=> Including motor, sealing flange, mechanical seal and impeller

A

A

Easy and reliable installation

The pumps are always delivered with a base plate

• The base plate is fastened onto a freely moving concrete plinth which is separated from the floor by a 20 mm / 0.8 in

thick rubber or cork mat

• The weight of the concrete base must be about 1.5 times the weight of the pump and motor

Easy and quick installation helps to minimize life cycle costs

=> No need for base plate grouting or motor / pump alignment

Note!

The motors are delivered with pre-lubricated and relubricated bearings. The motor with relubricated bearings is not allowed to run before the first lubrication has been made. Instructions can be found from the motor manual. There is sticker fan cover plate which warns about this.

a

Versatile surface treatment options

Inside surface treatment

•Standard surface cleaning for normal applications

•Special internal surface treatment on request

Outside surface treatment

•ISO 12944-5 C2l painting as standard

•Special outside treatment on request

a

a

a

Versatile tests and certificate options

Performance tests

•Capacity, head, efficiency, power and NPSHr tests according to ISO 9906:2012 / HI 14.6-2011

•Vibration test according to ISO 5199

Material inspections / Performance and NDT tests

•EN 10204: 2.1, 2.2, 3.1 and 3.2

Structural tests

•Balancing of impellers according to ISO 1940 grade 6.3

=> Grade 2.5 available on special request

Hydrostatic pressure test according to ISO 5199:2002

Inspection of assembly

•Dimensional checking of installation

•Dimensional checking of clearances

•Paint film thickness checking

•Final assembly checking

Other additional tests by request

a

a

a

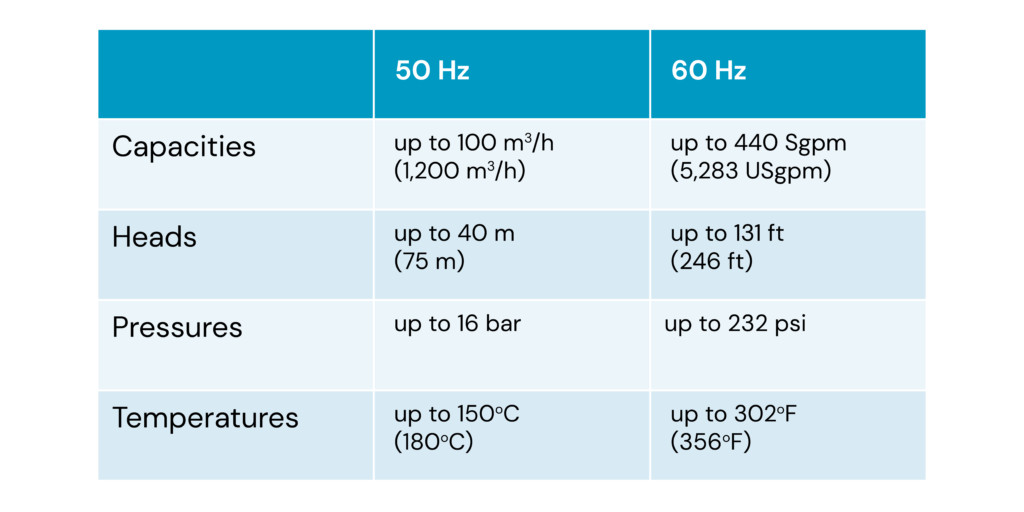

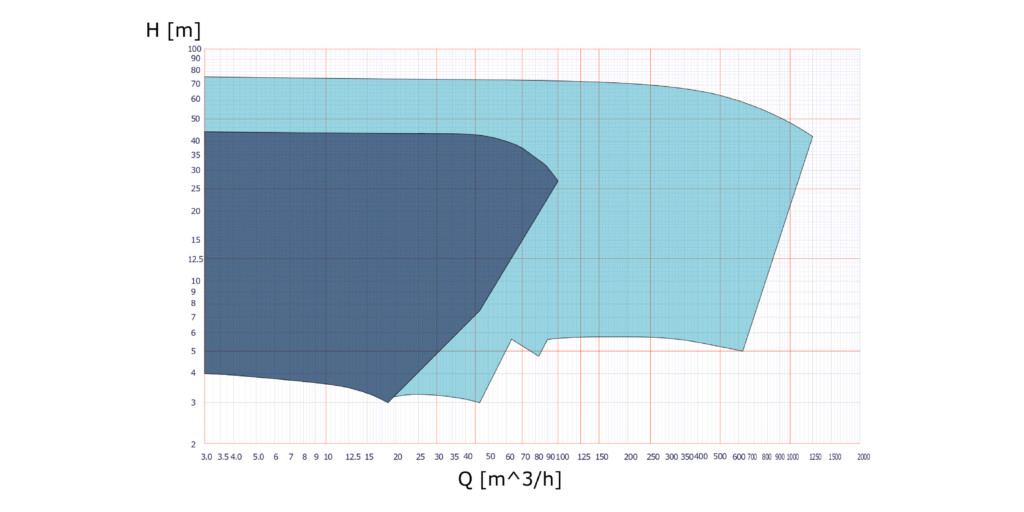

Operating data & Performance range

a

a

Where do we need pumps

Kolmeks develops and delivers pumps and other industrial solutions for a wide range of applications, such as residential construction, district heating, shopping centres, municipal buildings as well as spas and swimming pools.

We are specialized in creating customized solutions. See below the applications where our pumps are used.

A

Read more about the applications here

Kolmeks pumps:

www.kolmeks.com/en/products/pumps